全国咨询热线

0757-81942023

Concrete composition materials are generally cement, aggregate, water, mineral admixtures, chemical admixtures. For some concrete with special requirements, some special materials will be added according to the need.

Learn More

In 2016, there was a family building a new house in our village. If the house leaks when it is finished. For leaks, maybe everyone is familiar with, such as one or two leaks on the roof, which has made people very upset.

Learn More

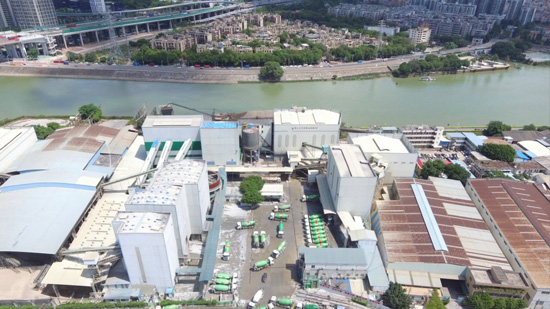

Every wait by gelatinizing material, aggregate and water to cooperate by appropriate proportion mix the mixture that makes, the artificial stone material that gets after moulding harden via pouring again, collectively for concrete.

Learn More

Check before operation: the control table of dry mortar mixing station should make the operator can see the work of each department, instrument indication signal is accurate and reliable, and the control table of electric dry powder mixing equipment should be filled with rubber board or dry wood.

Learn More

1, the whole station structure is tight, beautiful, generous and environmental protection;

2. Small floor area and flexible layout;

3, modular combination, free of foundation installation; It is convenient and fast to disassemble, assemble and transport, and the cycle is short.

4, high production efficiency, low energy consumption;

At the State Council executive meeting held on July 7, it was clearly stated that on the basis of trials, the country will launch the national trading market of carbon emission rights for the power generation industry at an appropriate time in July this year.

Learn More

Recently, the European Union’s "Red Mud Activation for the Production of Sustainable Cement" (ReActiv) joint project held a progress meeting, marking the official launch of the ReActiv project.

Learn More

Recently, Guangzhou Bulk Cement Management Office of Guangdong organized a supply and demand coordination meeting in the eighth branch of Guangzhou Rail Transit Line 11 to promote the application of machine-made sand in metro projects .

Learn More

In the future, the cement and concrete industries will use a variety of carbon capture and utilization technologies to capture carbon dioxide emitted into the air during production, use, recycling, and upgrading, so as to completely realize a closed cycle of carbon dioxide.

Learn More

Carbon Xprize, which cost US$20 million, distributed cash rewards to two teams from North America who were able to demonstrate how their method can eliminate meaningful carbon dioxide and produce concrete with performance equal to or better than traditional materials.

Learn More

A research team at Rice University has developed a new method that can convert waste tires into graphene, which can then be used in the manufacture of concrete.

Learn More

This elegant bench seat like a ribbon was designed and built by Landscape Forms and BMW Group's Designworks.

Learn More