Holland: Evaluate the geopolymer in 3D printing concrete

Researchers from Holland are exploring more potential of using concrete for 3D printing and have outlined their findings in the recently published "3D Printing Geopolymer Concrete Life Cycle Assessment: A Prior Study". With the growth of 3D printing and geopolymers, for those involved in the construction industry, the attractive companies and those in Portland and other regions are working hard to replace ordinary cement for environmental purposes, in order to reduce the use of materials and the amount of waste generated.

Four types of mold cores were used in previous studies relied on by researchers, providing sample mixtures created by 3D printing and more traditional techniques. Molds made by 3D printing show better environmental performance. For this research, the team's focus is on continuing to study environmental systems analysis, compared to previous work – especially when developing new solutions related to the pre-frame.

“We engaged the technology developers in the research process and discussed with them the potential future technology prospects, the potential market penetration, and the viability of future business data and scenarios,” the researchers said.

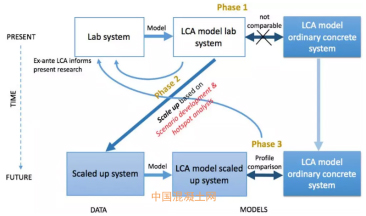

Life Cycle Assessment (LCA) is often used to assess the environmental impact of an existing “product or service system”, while the LCA is used in advance for the new product system before it is put into use.

Summary of the research process

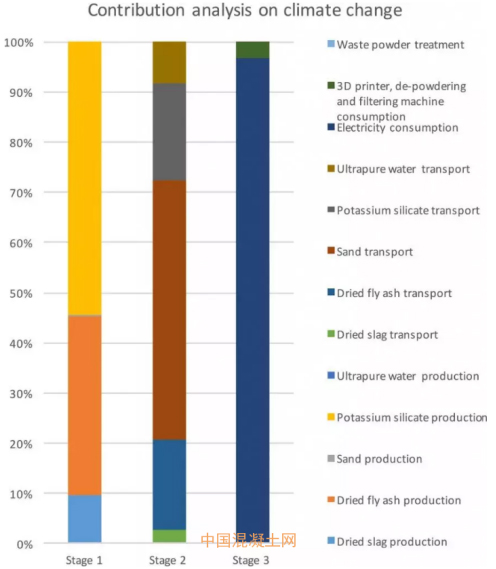

For 3D printed geopolymers, powders and bonding materials are key to concrete production, requiring slag, fly ash and sand. The powder was layered, then the silicate water additive was mixed and mixed, and then the binding liquid was extruded in a 3D printer. The researchers analyzed the three phases of the system, from raw material production to transportation to concrete manufacturing.

“The analysis is based on the impact scores that characterize all the impact categories considered in the assessment,” the researchers said.

Analysis of the contribution of climate change. The basic data used to create this diagram can be found in the support information.

The researchers pointed out that the hot spots are:

The electric power for 3D printing

Long transport distance

Manufacture of silicate

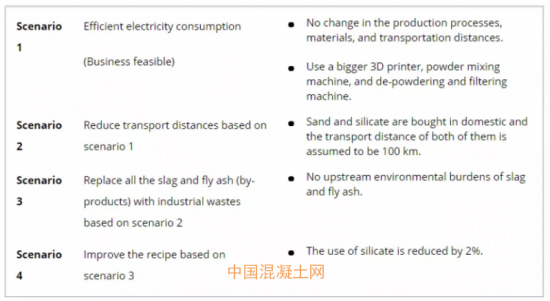

Four scenarios were created to improve hot spots. See the table below.

Details of four scenarios

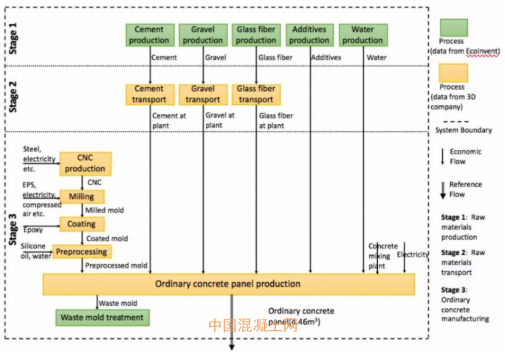

Researchers are also working to define environmental profiles for the geopolymer production of commercial use, and for technologies, they include typical raw materials such as cement, gravel, fiberglass, additives, and so on.

Ordinary concrete panel flow chart

“We assumed that, without interfering with the background processes obtained from the standard life cycle assessment database and literature, the technical improvements required to meet the four identified scenario conditions may occur. Therefore, changing the impact on laboratory-scale 3DGP technology will only affect the foreground system.," the researchers said.

They also conducted long-term evaluations of the technology based on three improve proposals.

Comparative characterization led to four cases. The basic data used to create this diagram can be found in the support information.

The pre-LCA study results presented here show some differences from previous 3D printing studies. This is mainly due to the different raw materials evaluated in conjunction with 3D printing technology. In the case described here, one of the raw materials in the formulation, namely silicate, has a considerable influence on the manufacturing process, and the result is higher than that of ordinary raw materials in 3D printing.

From the perspective of raw material transportation, 3DGP concrete has no advantage compared with ordinary concrete. For ordinary concrete, due to the maturity of the market, the raw material supply is operated on a full commercial scale. Ordinary concrete raw materials are not transported for long distances. These

aspects do provide room for improvement and rationalization of the use of resources.

3D printing now tends to not only allow rapid construction of homes and offices (even cars), but also in materials science, as research on concrete in other projects has also ranged from creating innovative reinforcements to optimizing parameters, even self-healing capsules.